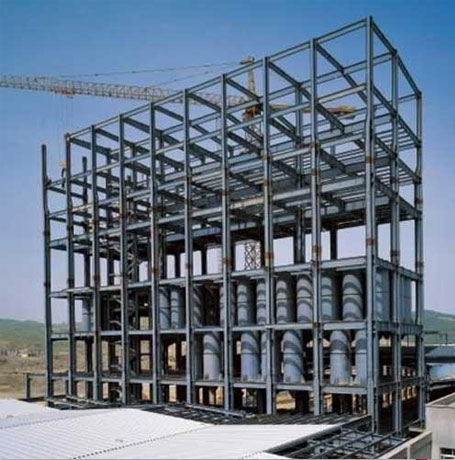

Modern construction and design trends indicate a growing demand for a wide array of structural steel systems. TR Structures offers extensive choices in this segment, available in a multitude of sizes, designs and specifications. Our Pre Engineered Buildings team of experienced engineers presents a winning combination of true structural strength and aesthetically pleasing, trending design styles to every single customer. Robust structure, high-quality raw material and superior service life remain our consistent attributes.

Since its commencement, TR Structures a main PEB producer has been occupied with conveying quality answers for help with framework advancement of the nation. Discussing Peb Structure Manufacturers, they have huge onus on their shoulder with regards to development.Thinking about this,

TR Structures is outfitted with most recent innovation, which is the reason it has gotten one of the trusted Peb Structure Manufacturers in Hyderabad. Sponsored by the absolute best architects, this PEB maker gives unequaled arrangements in key divisions like Industrial, Aviation and Commercial.

Steel structures and buildings have become a modern trend. The stylish, strong, and inexpensive steel structures are replacing the wooden and brick made structures. Brick and wooden structures include expensive construction and heavy maintenance costs. All of these expenses can be avoided by opting for durable, sturdy, and reliable steel structures or buildings.

Steel structural fabrication forms the core of the pre-engineering design and development of any housing or industrial facility. This is what the engineering and other factions of the facility would rest upon, and hence you would want to have the best people on the job for laying out this fundamental fabrication. The fabricator should have an understanding of pre-engineering design and how to best layout the structural fabrication, in accordance with the type of facility which is being built. As an example, if the fabrication is being done for a factory, the fabrication should incorporate any further compounding or extension requirements of the facility.

There are many benefits to incorporating structural steel in construction and other projects, but the products themselves can be complex and demand experienced structural steel fabrication teams to be successful.

Compared to other metal options, steel is stronger and cheaper. It offers more value in the range of fabrication industries where it is a staple.In the construction and other industries, structural steel usually arrives in the pre-fabrication phase and is fabricated on-site. Pre-fabrications reduces how much work needs to be done on-site, fast-tracking projects.Materials other than steel tend to be higher maintenance. For example, wood is vulnerable to bugs and can break down during corrosive weather conditions. Steel, meanwhile, is easily repaired and lasts a long time.Steel is environmentally friendly because it can be endlessly reused and recycled. It also requires less energy to produce and generates less carbon dioxide.

Structural steel is very strong and weighs up to a third less than comparable metals.It is very strong and weighs up to a third less than comparable metals.